Ultimate Guide to Container Home Foundations: Pier vs. Slab (For Permit Approval)

Engineering the connection between your steel box and the earth.

If there is one area of construction where “close enough” is not good enough, it is your foundation. As the Senior Structural Engineer here, I often see enthusiastic DIYers focus heavily on the aesthetics of the container—the cuts, the glass, the paint—while treating the foundation as an afterthought. This is a critical mistake. When you are building with shipping containers, you are dealing with unique structural loads that wood-framed houses simply do not have.

To secure a permit for container home foundations, you must prove to your local building department that your design accounts for point loads, uplift, frost heave, and soil bearing capacity. A standard residential foundation plan often won’t suffice because containers transfer weight through their four corners, not evenly along the walls. This guide is your technical manual for choosing, designing, and permitting the right foundation for your build.

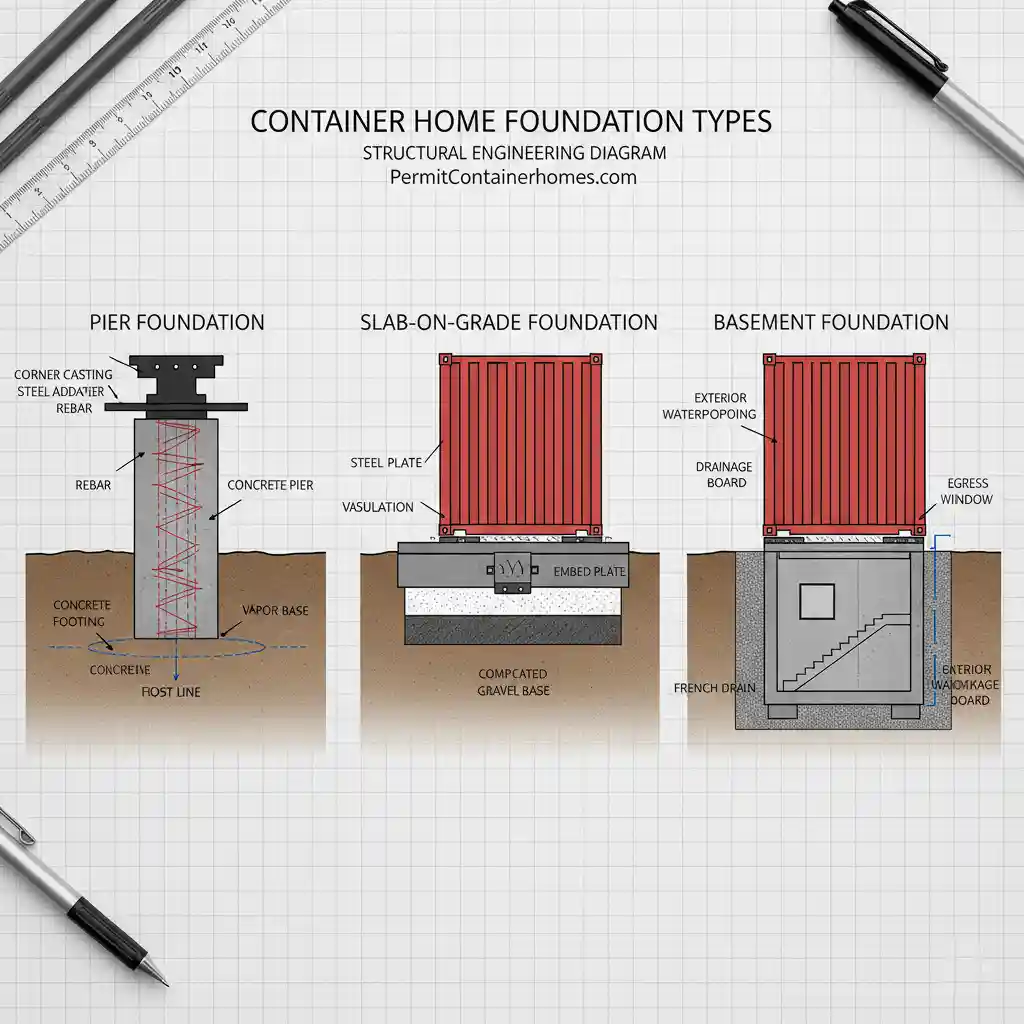

Whether you are considering simple concrete piers, a robust slab-on-grade, or a full basement, we are going to walk through the engineering realities of each. Let’s ensure your home stands on solid ground.

1. The Physics: Point Loads vs. Distributed Loads

Before we pour a single bag of concrete, you must understand how a shipping container behaves structurally. A traditional stick-built home transfers the weight of the roof and floors down through the studs, distributing the load relatively evenly along the foundation wall (perimeter load). Shipping containers are different.

Containers are monocoque structures designed to carry massive loads—up to 60,000 lbs or more—exclusively through their four corner castings. The corrugated steel walls contribute to rigidity, but they are not designed to bear the primary vertical load unless specifically reinforced. This means your foundation design must account for massive Point Loads at specific coordinates.

When we design container home foundations for our clients, we calculate the “Dead Load” (the weight of the empty container + insulation + drywall + fixtures) and the “Live Load” (people + furniture + snow). For a standard 40ft High Cube, the Dead Load alone can exceed 15,000 lbs once finished. That weight is concentrated on four 6×6 inch steel squares. Your foundation must be able to accept that pressure without settling.

2. Pier Foundations: The Cost-Effective Favorite

Pier foundations are arguably the most popular choice for container homes. They elevate the home off the ground, require less concrete than a slab, and are relatively easy to level. A pier system typically consists of concrete columns reinforced with rebar, resting on a spread footing below the frost line.

Why Choose Piers?

From an engineering standpoint, piers align perfectly with the structural nature of a container. Since the container wants to be supported at the corners, placing a robust pier under each corner casting is the most efficient transfer of load. For a 40ft container, we often recommend intermediate piers to prevent floor deflection (bounciness), usually spaced every 10 to 14 feet.

Structural Requirements for Permitting

To get a pier foundation approved, your site plan must detail:

- Footing Depth: The base of the pier must be below the local frost line to prevent frost heave. In northern states like New York, this could be 48 inches or deeper.

- Rebar Schedule: Vertical rebar (usually #4 or #5 bars) must tie the pier to the footing to resist uplift forces.

- Diameter: Most engineers specify 12-inch to 18-inch diameter piers depending on soil bearing capacity.

📖 View Typical Pier Installation Steps

1. Excavation: Augering holes to the required frost depth.

2. Footing Pour: Pouring a concrete “pad” at the bottom of the hole (often 24″ wide).

3. Rebar Cage: Inserting a tied rebar cage that extends from the footing up through the column.

4. Formwork: Using Sonotubes (cardboard forms) to shape the pier above ground.

5. The Pour: Filling the tube with 3,000+ PSI concrete and vibrating to remove air pockets.

6. Hardware: Wet-setting J-bolts or embed plates into the top of the wet concrete for later welding.

3. Slab-on-Grade: The Traditional Approach

A slab-on-grade foundation involves pouring a concrete “mat” directly on the ground. This acts as both the foundation and the subfloor of the first level. While more expensive than piers due to the volume of concrete, slabs offer significant advantages in terms of thermal mass, pest control, and simplified utility rough-ins.

Stem Wall vs. Monolithic Slab

There are two primary ways to pour a slab for container home foundations:

- Monolithic Slab: The footings and the floor are poured in one single operation. This is faster and works well in warmer climates like Texas or Florida where frost depth is minimal.

- Stem Wall: A footing is poured first, followed by a masonry or concrete wall (the stem), and finally the slab is poured inside. This is preferred in areas with significant frost lines or sloped sites.

The critical engineering detail for slabs is the “embed plate.” We typically specify steel plates with headed studs to be cast directly into the concrete corners. Once the concrete cures, you set the container down and weld the corner castings directly to these embedded plates. This creates an immense resistance to lateral forces (wind/earthquakes).

4. Full Basements: Maximizing Square Footage

If you are building on a sloped lot or simply need more space without expanding your footprint, a basement foundation is a powerful option. A container home sits on top of the basement walls (usually poured concrete or ICF – Insulated Concrete Forms). This effectively doubles your square footage.

However, this is the most technically complex option. The basement walls must be designed to retain the soil pressure from the outside. Furthermore, the connection between the steel container and the concrete wall requires careful detailing to prevent water intrusion and thermal bridging.

You will need to consult our Building Codes Guide to understand the egress (exit) requirements. If you have a basement with sleeping rooms, you must have egress windows or a walk-out door, regardless of the container structure above.

5. The “Hidden” Variable: Soil Mechanics

You can design the strongest concrete pier in history, but if the soil underneath it is weak, your house will sink. This is where “Bearing Capacity” comes in. Soil bearing capacity is measured in PSF (Pounds per Square Foot). Solid bedrock might hold 12,000 PSF, while soft clay might only hold 1,500 PSF.

For permit approval, many jurisdictions require a Geotechnical Report (soil test). If you don’t have one, the International Residential Code (IRC) generally allows us to assume a conservative value (often 1,500 or 2,000 PSF), which forces us to design larger, more expensive footings to spread the weight out.

6. Anchoring: Wind and Seismic Considerations

Gravity isn’t the only force we fight. We also fight “Uplift” (wind trying to pull the house up) and “Shear” (wind or earthquakes pushing the house sideways). Because shipping containers are relatively light compared to their surface area, they are basically large steel sails. Secure anchoring is non-negotiable.

Your container home foundations plan must specify the connection hardware. We do not rely on gravity.

📖 View IRC R403.1.6 Anchorage Requirements

Code Reference: While the IRC references wood sills, the engineering principle applies to steel. Foundations must provide anchorage to resist wind-induced uplift and overturning.

Common Methods:

1. Weld Plates: Steel plates with J-bolts embedded in concrete. Container corners are welded to plates.

2. Twist Locks: similar to how containers are secured to ships/trucks, bolted into the concrete.

3. Epoxy Anchors: Drilled into cured concrete if embed plates were missed (retrofit only).

7. Cost & Feasibility Comparison

Choosing the right foundation is often a balance between budget, site conditions, and DIY capabilities. Below is a comparison based on current market averages for a standard 3-container footprint (approx. 960 sq ft).

| Feature | Pier Foundation | Slab-on-Grade | Full Basement |

|---|---|---|---|

| Est. Cost (DIY) | $4,000 – $7,000 | $10,000 – $15,000 | $25,000+ |

| Est. Cost (Pro) | $8,000 – $12,000 | $18,000 – $25,000 | $40,000+ |

| Excavation | Minimal (Holes only) | Moderate (Grading) | Massive (Deep dig) |

| Insulation | Requires Spray Foam under floor | Rigid foam under slab | Exterior wall insulation |

| Best For… | Sloped sites, DIYers, Budget | Flat sites, Accessibility | Max space, Cold climates |

If you are unsure which route to take, consider checking our Cost Estimator or browsing our shop for guides that break down the material lists for each type.

Start With the Right Plan

Don’t guess on your foundation. Every plan set we sell includes engineer-approved foundation specifications for permit submission.

Browse Permit-Ready PlansIf you find a plan you love but need to adjust it for your local soil conditions or specific foundation preference—such as switching from piers to a basement—our team can help. We offer a professional plan modification service after purchase. Just contact us for a personalized quote!

Disclaimer: The information provided in this guide is for educational purposes regarding container home foundations and does not constitute a signed engineering contract. Foundation requirements vary drastically by soil type and location. Always consult with a local Professional Engineer (PE) to verify your site-specific loads before pouring concrete.