Step-by-Step Guide: Building a Home Out of Shipping Containers

Complete IRC-Compliant Process from Permits to Certificate of Occupancy

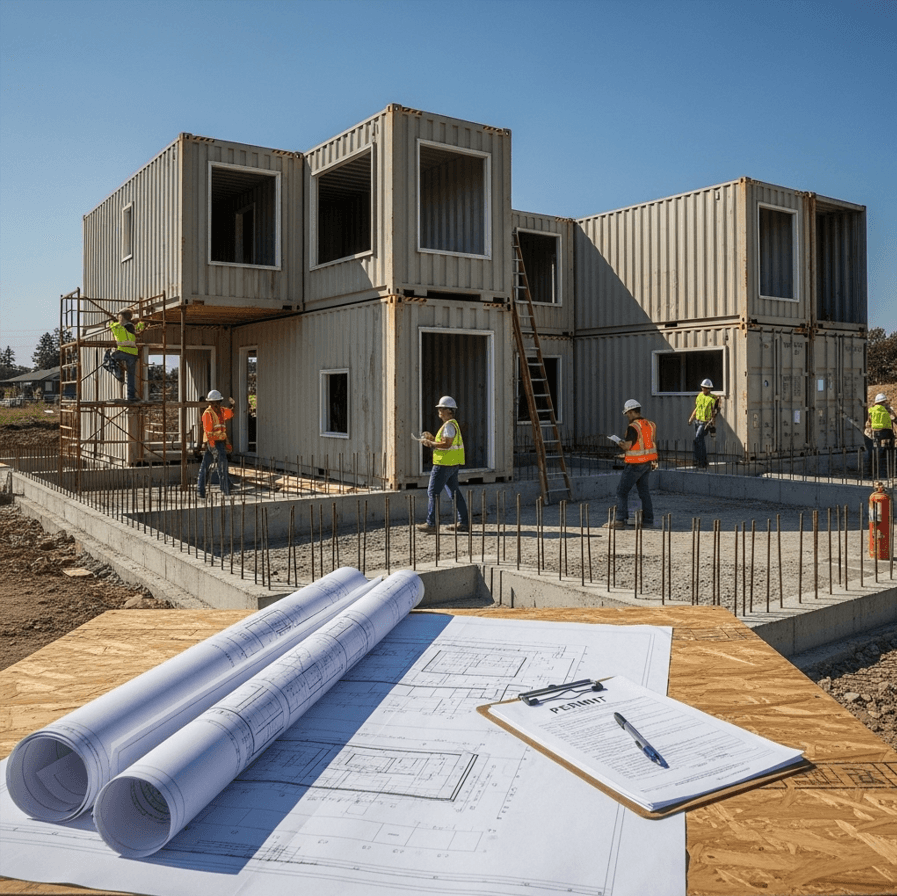

Building a home out of shipping containers has transformed from an experimental housing concept into a mainstream construction method backed by established building codes and proven engineering practices. This comprehensive guide walks you through every phase of container home construction, from initial planning and permit applications to final inspections and occupancy approval.

The process of building a home out of shipping containers follows the same regulatory framework as traditional residential construction, requiring compliance with the 2021 International Residential Code (IRC) and International Building Code (IBC). Understanding these requirements from the outset prevents costly delays and ensures your container home meets all safety and structural standards for your jurisdiction.

This mega guide connects you to every resource you’ll need throughout your container home journey, from selecting and purchasing plans through our complete plan collection to understanding building codes and permits specific to container construction. Whether you’re planning a single-container tiny home or a multi-story residence, this step-by-step framework ensures code compliance and successful project completion.

Understanding Container Home Construction Fundamentals

The foundation of successfully building a home out of shipping containers begins with understanding how these industrial structures transition into code-compliant residential dwellings. Shipping containers, originally designed for cargo transport, must undergo significant modifications and engineering analysis to meet residential building standards established by the IRC and IBC.

Standard shipping containers come in two primary sizes: 20-foot units providing approximately 160 square feet of floor space, and 40-foot units offering 320 square feet. High-cube containers add an extra foot of interior height, providing 9.5 feet of clearance compared to standard 8.5-foot containers. These dimensions form the modular basis for your design, whether you’re planning a compact single-container dwelling or a multi-container residence.

Container Selection and Structural Integrity

When building a home out of shipping containers, selecting the right units is critical for structural success. One-trip or “new” containers—those that have made only a single journey from manufacturer to destination—provide the best foundation for residential construction. These containers haven’t been exposed to potentially hazardous cargo or years of corrosive salt air during ocean transport.

Inspect containers thoroughly before purchase, examining corner posts, cross members, flooring condition, and structural integrity. Look for rust, significant denting, or previous repairs that might compromise load-bearing capacity. California and several other states require documentation proving containers haven’t contained toxic or radioactive materials when used for human habitation—verify this documentation before finalizing any purchase.

Site Selection and Preliminary Planning

Building a home out of shipping containers requires careful site selection considering access for container delivery, foundation requirements, and utility connections. Container delivery typically requires crane service or large flatbed trucks, necessitating at least 14 feet of vertical clearance and adequate turning radius for heavy equipment. Verify your site provides this access before committing to property purchase or container delivery.

Zoning regulations significantly impact container home feasibility. Before purchasing land or containers, confirm with your local planning department that residential container construction is permitted in your chosen zone. Some jurisdictions classify shipping containers differently than traditional building materials, requiring special use permits or conditional approvals. Early verification prevents costly surprises later in the process.

IRC/IBC Code Requirements for Container Homes

Successfully building a home out of shipping containers requires strict adherence to the International Residential Code (IRC) and International Building Code (IBC), both published by the International Code Council. These codes establish minimum requirements for structural integrity, fire safety, energy efficiency, and occupant protection that apply equally to container homes and traditionally-built residences.

The IRC governs one- and two-family dwellings and townhouses up to three stories in height. Container homes falling within these parameters must comply with IRC requirements for foundations, structural design, fire protection, mechanical systems, plumbing, and electrical installations. Larger or taller container structures fall under IBC jurisdiction, which imposes additional requirements for commercial-grade construction and fire suppression systems.

Permit Application Requirements

The permit application process for building a home out of shipping containers follows the same framework as traditional residential construction, with additional documentation addressing container-specific modifications. Your application must identify and describe the work to be covered, describe the land by legal description or street address, indicate the intended use and occupancy, be accompanied by construction documents, state the valuation of the proposed work, and be signed by the applicant or authorized agent.

View Full IRC Section R105.3 – Application for Permit

IRC Section R105.3 – Application for permit

To obtain a permit, the applicant shall first file an application therefor in writing on a form furnished by the department of building safety for that purpose. Such application shall: 1. Identify and describe the work to be covered by the permit for which application is made. 2. Describe the land on which the proposed work is to be done by legal description, street address or similar description that will readily identify and definitely locate the proposed building or work. 3. Indicate the use and occupancy for which the proposed work is intended. 4. Be accompanied by construction documents and other information as required in Section R106.1. 5. State the valuation of the proposed work. 6. Be signed by the applicant or the applicant’s authorized agent. 7. Give such other data and information as required by the building official.

Source: 2021 International Residential CodeConstruction Documents and Engineering Requirements

When building a home out of shipping containers, submittal documents consisting of construction documents must be submitted in two or more sets with each permit application. The construction documents shall be drawn upon suitable material and be of sufficient clarity to indicate the location, nature and extent of the work proposed and show in detail that it will conform to the provisions of the IRC and relevant laws, ordinances, rules and regulations.

For container homes specifically, construction documents must address structural modifications to container walls and roofs, foundation design capable of supporting concentrated container corner loads, insulation and vapor barrier systems meeting energy code requirements, and all electrical, plumbing, and mechanical system installations. Many jurisdictions require these documents to be prepared or stamped by a licensed Professional Engineer, particularly for structural calculations and foundation design.

The International Code Council provides comprehensive resources including code books, interpretation services, and training programs to help builders understand specific requirements for innovative construction methods like container homes. Their website offers access to digital versions of all I-Codes and regular updates on code amendments adopted by various jurisdictions.

Foundation and Structural Requirements

Building a home out of shipping containers presents unique foundation challenges due to the concentrated loads at container corners. Unlike traditional residential construction where loads distribute across continuous foundation walls, container homes transfer their entire weight through four corner castings per container unit. Foundation design must account for these point loads while meeting IRC requirements for frost depth, soil bearing capacity, and structural stability.

Common foundation types for container homes include concrete pier systems, full concrete slabs, strip footings, and pile foundations for challenging soil conditions. Regardless of foundation type selected, the design must comply with IRC Chapter 4 requirements for foundation construction, including minimum concrete strength of 2,500 PSI, proper reinforcement placement, and adequate embedment below frost line for your climate zone.

Professional Engineer Review and Approval Process

Building a home out of shipping containers requires Professional Engineer (PE) involvement in nearly all US jurisdictions due to the non-conventional nature of container construction and the structural modifications necessary to create habitable spaces. A licensed PE reviews your plans, performs site-specific engineering calculations, and provides stamped drawings that building departments require for permit approval.

The PE’s role extends beyond simple plan review. They conduct structural analysis accounting for your specific site conditions including soil bearing capacity, seismic design category, wind loads, snow loads, and frost depth requirements. These site-specific factors significantly impact foundation design, connection details, and structural reinforcement requirements—variables that pre-designed plans cannot fully address without local engineering input.

What Your Professional Engineer Reviews

When building a home out of shipping containers, your PE examines every structural aspect of the design. They verify that container modifications—including wall openings for windows and doors—maintain adequate structural integrity through proper reinforcement. They calculate foundation loads accounting for dead loads (the weight of containers, finishes, and fixed equipment) and live loads (occupants, furniture, and snow on roofs).

The PE also reviews mechanical, electrical, and plumbing systems for code compliance, though specialized MEP engineers may be engaged for complex systems. They ensure insulation and vapor barrier strategies meet energy code requirements established by the International Energy Conservation Code (IECC). For additional guidance on residential building energy requirements, the U.S. Department of Energy provides comprehensive resources on meeting energy code standards for innovative construction methods including container homes.

After purchasing comprehensive plans from Permitcontainerhomes.com, you’ll work with a licensed PE who will review the detailed documentation, adapt it for your site conditions, and provide stamped drawings required for permit submission. Our plans are specifically designed to align with 2021 IRC/IBC building code standards, providing your PE with complete architectural drawings, structural details, electrical layouts, and plumbing systems that streamline their review process.

PE Selection and Timeline

Selecting the right PE for building a home out of shipping containers requires finding professionals experienced with alternative construction methods and familiar with your local building department’s expectations. Many PEs specialize in traditional wood-frame construction and may require additional time to familiarize themselves with container-specific engineering considerations.

The PE review process typically requires 2-4 weeks for straightforward single-story designs and up to 6-8 weeks for complex multi-story or large-scale projects. This timeline includes initial plan review, engineering calculations, preparation of stamped drawings, and any revisions requested by the building department during their review process. Factor this timeline into your overall project schedule to avoid delays.

Step-by-Step Construction Phases

Building a home out of shipping containers follows a sequential process with specific inspection requirements at each phase. The IRC mandates inspections at foundation stage, rough-in stage for utilities, framing stage, and final completion. Understanding these phases and their requirements ensures smooth progression through your project without delays or failed inspections.

Phase 1: Site Preparation and Foundation

Construction begins with site preparation including clearing, grading, and establishing proper drainage. The site must be level before foundation construction begins, verified using laser levels or professional surveying equipment. Excavation for foundations must extend below the frost line depth specified in IRC Table R301.2(1) for your climate zone—this depth ranges from zero in southern states to 60 inches or more in northern regions.

Foundation inspection occurs after trenches or basement areas are excavated and any required forms erected with reinforcing steel in place and supported prior to placing concrete. The IRC specifies that the building official shall make this inspection to verify proper foundation depth, reinforcement placement, and anchor bolt positioning before concrete placement proceeds.

View Full IRC Section R109.1.1 – Foundation Inspection

IRC Section R109.1.1 – Foundation inspection

Inspection of the foundation shall be made after poles or piers are set or trenches or basement areas are excavated and any required forms erected and any required reinforcing steel is in place and supported prior to the placing of concrete. The foundation inspection shall include excavations for thickened slabs intended for the support of bearing walls, partitions, structural supports, or equipment and special requirements for wood foundations.

Source: 2021 International Residential CodePhase 2: Container Delivery and Placement

Once foundations cure completely (typically 7-14 days for full-strength concrete), containers can be delivered and positioned. Professional crane service precisely places containers on foundation supports, ensuring perfect level and proper alignment. Container placement accuracy is critical—even small deviations compound across multiple units in multi-container designs, creating structural challenges and finish complications.

Containers must be secured to foundations using welded connections or through-bolted anchor systems. These connections prevent uplift during high winds and resist lateral seismic forces in earthquake-prone regions. Connection design should appear on your PE-stamped structural drawings and must be inspected before proceeding with modifications or interior construction.

Phase 3: Structural Modifications and Rough-In

Building a home out of shipping containers requires cutting openings for doors, windows, and interior circulation. Each opening must be reinforced before cutting to maintain structural integrity. Typical reinforcement uses welded steel tubing or angle iron extending at least 6 inches beyond cut edges. All exposed steel edges require grinding smooth and treatment with rust-inhibitive primer.

The IRC requires rough inspection of plumbing, mechanical, gas and electrical systems prior to covering or concealment, before fixtures or appliances are set or installed, and prior to framing inspection. For container homes, this inspection verifies that all utility rough-ins comply with code requirements before insulation and interior finishes conceal the work.

| Construction Phase | Typical Timeline | Cost Range | Key Inspection |

|---|---|---|---|

| Plan Purchase | Immediate | Varies by size | N/A |

| PE Review & Stamping | 2-4 weeks | $2,000-$5,000 | N/A |

| Permit Review | 4-12 weeks | $500-$2,000 | Plan Check |

| Foundation Construction | 1-3 weeks | $8,000-$25,000 | Foundation |

| Container Delivery & Placement | 1-2 days | $3,500-$8,000 | Placement Verification |

| Modifications & Rough-In | 4-8 weeks | $15,000-$40,000 | Rough Inspection |

| Insulation & Interior Finish | 4-8 weeks | $20,000-$50,000 | Framing & Insulation |

| Final Systems & Fixtures | 2-4 weeks | $10,000-$30,000 | Final Inspection |

Note: Timelines and costs vary significantly by location, project complexity, site conditions, and local jurisdiction workload. These are general estimates for planning purposes. Container costs, crane rental, and specialized labor rates differ substantially across regions. Always obtain local quotes and verify requirements with your building department.

Phase 4: Insulation and Interior Finishing

Proper insulation is critical when building a home out of shipping containers due to metal’s thermal conductivity. Closed-cell spray foam insulation performs best in container applications, providing both thermal resistance (R-20 to R-24 at 3-4 inches thickness) and vapor barrier protection. The U.S. Department of Energy recommends R-values based on climate zones—container homes typically require higher R-values than code minimums due to metal thermal bridging effects.

Frame and masonry inspection occurs after the roof, framing, firestopping, draftstopping and bracing are in place and after the plumbing, mechanical and electrical rough inspections are approved. For container homes, this inspection verifies that interior framing, insulation installation, and all structural modifications comply with approved plans and code requirements before applying interior finishes.

Cost Breakdown and Project Timeline

Building a home out of shipping containers requires careful budget planning across multiple cost categories including materials, professional services, permits, and construction labor. Understanding these costs upfront and planning for contingencies prevents budget overruns that derail projects mid-construction. Total costs vary dramatically based on size, complexity, location, and finish level—ranging from $150-$250 per square foot for basic builds to $300+ per square foot for high-end custom designs.

Material and Container Costs

Container acquisition represents your first major expense when building a home out of shipping containers. One-trip 40-foot high-cube containers typically cost $3,200-$4,800 depending on location and market conditions. Standard height containers run $500-$1,000 less. You’ll need additional budget for container delivery and crane service—expect $800-$2,000 per container for delivery within 100 miles and $1,500-$3,500 for professional crane placement per day of service.

Foundation costs depend heavily on soil conditions and chosen foundation type. Concrete pier foundations for single-story container homes typically range $8,000-$15,000 for basic designs. Full slab foundations cost $12,000-$25,000 depending on size and site preparation requirements. Challenging soil conditions requiring deep piles or extensive excavation can push foundation costs to $30,000 or more. Always obtain soil testing and engineering analysis before finalizing foundation budgets.

Professional Service Costs

Professional Engineer review and stamping typically costs $2,000-$5,000 as discussed in Section 3. This investment is mandatory in most jurisdictions and provides the structural certification your building department requires. Additional engineering costs may arise for complex sites requiring geotechnical reports ($1,500-$3,500), specialized seismic analysis, or custom structural solutions for large openings or cantilevers.

Building permit fees vary by jurisdiction but typically calculate as a percentage of project valuation plus flat fees for plan review and inspections. Expect $500-$2,000 for permits on modest container homes and $2,000-$5,000+ for larger or more complex projects. Some jurisdictions impose additional fees for alternative construction methods or require special inspections at higher rates than standard residential construction.

If you’re not serving as your own general contractor, professional construction management typically adds 15-25% to total project costs. However, experienced contractors familiar with building a home out of shipping containers can save money through efficient sequencing, trade coordination, and avoiding costly mistakes that inexperienced builders make. Balance DIY cost savings against the value of professional expertise, especially for your first container project.

Construction and Systems Costs

Structural modifications including cutting openings, welding reinforcements, and joining multiple containers typically cost $5,000-$15,000 per container depending on complexity. Simple modifications with a few window and door openings fall on the lower end, while extensive cuts creating open floor plans or multi-story connections require more engineering and fabrication labor.

Mechanical, electrical, and plumbing (MEP) systems follow similar cost patterns to traditional construction but may require specialized approaches for container applications. Budget $8,000-$15,000 for basic electrical systems, $6,000-$12,000 for plumbing, and $8,000-$20,000 for HVAC depending on system complexity and regional labor rates. Mini-split HVAC systems popular in container homes typically cost less to install than traditional forced-air systems but provide efficient heating and cooling.

Insulation represents a critical investment when building a home out of shipping containers. Closed-cell spray foam insulation costs $1.50-$3.00 per square foot at 2-3 inch thickness. For a 40-foot container with approximately 650 square feet of wall and ceiling area, expect $1,000-$2,000 for insulation. Interior finishes including framing, drywall, flooring, cabinetry, and fixtures range $30,000-$80,000 depending on finish quality and complexity.

| Cost Category | Budget Range | Key Factors |

|---|---|---|

| Container Acquisition (40′ HC) | $3,200-$4,800 each | Condition, location, market timing |

| Delivery & Crane Service | $2,500-$5,500 total | Distance, site access, placement complexity |

| Plan Purchase | Varies by design | Size, complexity, customization needs |

| PE Review & Stamping | $2,000-$5,000 | Project complexity, local PE rates |

| Building Permits & Fees | $500-$5,000+ | Jurisdiction, project valuation |

| Foundation Construction | $8,000-$30,000+ | Soil conditions, foundation type, size |

| Structural Modifications | $5,000-$15,000 per container | Number of openings, complexity |

| MEP Systems (Complete) | $22,000-$47,000 | System complexity, regional rates |

| Insulation & Weatherproofing | $3,000-$8,000 | Insulation type, R-value requirements |

| Interior Finishes | $30,000-$80,000 | Finish quality, fixtures, cabinetry |

| Contingency (15-20%) | Varies by total budget | Project complexity, site conditions |

Important: Costs vary significantly by geographic location, current material prices, local labor rates, and project-specific requirements. These ranges represent typical costs across diverse US markets but your actual costs may differ. Obtain detailed quotes from local contractors and suppliers for accurate budget planning. Container availability and pricing fluctuate based on international shipping patterns and regional demand.

Project Timeline Planning

Building a home out of shipping containers typically requires 6-12 months from permit application to certificate of occupancy for standard designs, with complex projects extending to 18 months or more. The longest delays usually occur during permit review (4-12 weeks) and can extend further if plan revisions are required. Fast-track jurisdictions may approve straightforward plans in 2-3 weeks, while others require multiple review cycles.

Construction timelines depend on weather, contractor availability, and inspection scheduling. Foundation work requires 1-3 weeks plus curing time. Container modifications and rough-in work spans 4-8 weeks. Interior finishing requires another 4-8 weeks. Factor additional time for inspection scheduling—some busy building departments require 2-3 days notice for inspections, while others inspect within 24 hours of request.

Expert Tips and Essential Resources

Successfully building a home out of shipping containers requires knowledge, planning, and access to reliable resources throughout your project. These expert insights help you avoid common pitfalls and navigate challenges that frequently emerge during container home construction. Whether you’re just beginning research or actively managing construction, these tips provide practical guidance for each project phase.

Critical Success Factors

- Start with comprehensive plans designed for PE review: Our complete plan sets available through the shop provide detailed architectural drawings, structural specifications, and MEP layouts that streamline your Professional Engineer’s review process. Plans designed to align with 2021 IRC/IBC standards give your PE a solid foundation to work from, reducing review time and costs compared to starting from scratch or adapting generic plans.

- Engage your building department early: Schedule a pre-application meeting before purchasing containers or finalizing designs. Building officials can identify jurisdiction-specific requirements, explain local amendments to IRC/IBC codes, and clarify inspection procedures. This early engagement prevents costly design changes after container purchase and establishes positive relationships with officials who ultimately approve your project.

- Budget realistically including all professional services: Many aspiring container home builders underestimate total costs by focusing only on container acquisition and construction labor. Professional Engineer review ($2,000-$5,000), permits ($500-$5,000), site preparation, utility connections, and finish materials add substantially to project budgets. Review the detailed cost breakdown in Section 5 and obtain local quotes before committing to your project.

- Prioritize insulation and moisture management: Metal containers conduct heat and cold efficiently, creating condensation problems and uncomfortable interior temperatures without proper insulation and vapor barriers. Invest in closed-cell spray foam insulation providing both thermal resistance and moisture protection. Poor insulation decisions haunt container homes for decades through high energy bills, comfort problems, and moisture damage to interior finishes.

- Select containers carefully with thorough inspections: Not all containers are suitable for residential construction. Verify structural integrity, check for previous cargo contamination, and obtain documentation proving food-grade or one-trip status. Spending extra for quality containers prevents structural problems and contamination concerns that can emerge years after construction. For detailed container selection guidance, see our First Container Home Guide 2025.

- Plan for realistic timelines including permit review: Building departments require 4-12 weeks or more for plan review and permit issuance. PE review adds another 2-4 weeks before permit application. Weather delays, inspection scheduling, and material lead times extend construction timelines beyond optimistic projections. Add buffer time to every phase when planning your project schedule and financing.

- Document everything for inspections and future reference: Maintain complete records of permits, PE-stamped drawings, inspection approvals, material specifications, and warranty information. Building inspectors require approved plans on site during inspections. Future owners will need this documentation for renovations, refinancing, or sale. Organized documentation also helps if questions arise years after construction completion.

Common Challenges and Solutions

Building a home out of shipping containers presents unique challenges that differ from traditional construction. Understanding these common issues and their solutions helps you prepare effective strategies before problems arise. Zoning restrictions in some jurisdictions prohibit or severely limit container construction—verify zoning approval before purchasing property or containers. Some builders successfully obtain variances or conditional use permits by presenting well-engineered plans demonstrating code compliance.

Financing challenges affect many container home builders since lenders often hesitate to finance alternative construction methods. Construction-to-permanent loans specifically designed for custom builds generally work better than traditional mortgages for container homes. Providing lenders with complete PE-stamped plans, detailed cost breakdowns, and comparable sales data for container homes helps secure financing approval. Some builders use personal loans, home equity lines, or cash financing to avoid mortgage complications.

Container modifications require specialized skills combining welding, steel fabrication, and construction knowledge. Not all contractors possess these skills or willingness to work with alternative building methods. Interview multiple contractors specifically asking about container home experience. Contractors experienced with steel buildings, welding shops, or industrial facilities often adapt well to container construction even without specific container home experience.

Moving Forward With Your Project

With comprehensive planning, appropriate professional support, and realistic expectations, building a home out of shipping containers delivers an innovative, sustainable, and cost-effective housing solution. The step-by-step process outlined in this guide—from initial planning through final inspection—provides a proven framework for successful container home completion that meets all IRC/IBC requirements and your local jurisdiction’s expectations.

Your next steps include exploring comprehensive plan packages designed specifically for container construction, connecting with a qualified Professional Engineer in your area, and consulting your local building department about jurisdiction-specific requirements. These foundational actions set your project on the path to successful completion and create your unique container home that serves you for decades to come.

Ready to Start Your Container Home Project?

Explore our collection of comprehensive container home plans designed to align with 2021 IRC and IBC building code standards. Each plan includes complete architectural drawings, structural details, electrical layouts, plumbing systems, and beautiful 3D visualizations—everything your Professional Engineer needs for efficient review.

Browse Complete Plan Collection →Need Plan Modification? If you find a plan you love but need to adjust it for your local climate or personal needs—such as moving a window or adding a door—our team can help. We offer a professional plan modification service after purchase. Simply contact us with your modification needs, and we’ll provide a personalized quote.

Professional Engineering & Plan Documentation Disclaimer

Important: Our plans are permit-ready but require review and stamping by a local licensed Professional Engineer (PE) in your jurisdiction. Final approval is subject to local building codes and regulations. We recommend consulting your local building department to verify all requirements.

Refund Policy: Due to the digital nature of our plans, all sales are final. Please review our Refund Policy for details.