How Wide is a Container Home? 5 Critical Interior Planning Tips

The definitive guide to managing millimeters, insulation, and IRC codes in your build

If you are planning a build, the single most important question you must ask is: how wide is a container home? While the brochure might say “8 feet,” the reality of a finished, code-compliant home is significantly different. Determining exactly how wide is a container home after framing, insulation, and drywall is the calculation that will make or break your floor plan.

Many first-time builders assume they have plenty of room, only to find that once they add the required R-value insulation, their hallway is illegal, or their queen-sized bed blocks the walking path. Understanding how wide is a container home is not just about measuring the steel box; it is about calculating the “wall stack”—the cumulative thickness of every layer between the exterior world and your living room.

Our comprehensive plans are engineered with this specific constraint in mind. We prioritize high-performance insulation strategies that maximize interior volume, ensuring that when you ask how wide is a container home built from our designs, the answer is “wide enough to be comfortable and compliant.”

The Raw Numbers: ISO Dimensions vs. Reality

To accurately answer how wide is a container home, we must start with the International Standards Organization (ISO) 668 specifications. The external width of a standard intermodal shipping container is exactly 8 feet (2.44 meters). However, you cannot live on the exterior. The corrugated steel walls have a profile depth of approximately 2 inches (50mm), which immediately impacts the interior measurement.

The “Wall Stack” Calculation

The confusion regarding how wide is a container home usually stems from ignoring the wall stack. A standard residential wall stack includes:

- Air Gap (optional but common): 0.5 – 1 inch

- Framing (Studs): 3.5 inches (for 2×4) or 1.5 inches (turned flat)

- Insulation: Fills the framing cavity

- Interior Cladding (Drywall): 0.5 inch

If you build standard 2×4 walls on both sides, you lose approximately 9 inches of total width. Suddenly, the answer to “how wide is a container home?” drops from 8 feet to barely 6 feet, 11 inches—which is a major problem for code compliance.

The International Code Council (ICC) publishes strict guidelines on minimum room dimensions. If your finished width drops below certain thresholds, your “bedroom” may legally become a “storage closet,” drastically affecting your property value and permit approval.

📖 View Full IRC Section R304.2 Text

IRC Section R304.2 – Minimum Dimensions:

Habitable rooms shall be not less than 7 feet (2134 mm) in any horizontal dimension.

Exception: Kitchens.

Source: 2021 International Residential Code

IRC Code Requirements for Widths

When you ask how wide is a container home, the building inspector is asking, “Is it wide enough to be legal?” The 2021 International Residential Code (IRC) Section R304.2 mandates that habitable rooms must have a horizontal dimension of at least 7 feet. This is the critical number. If your insulation strategy reduces the width to 6 feet, 11 inches, you have failed inspection.

This reality makes the question of how wide is a container home the most critical calculation in your entire project. You are working with a margin of error of less than 4 inches on either side. This is why “standard” construction methods often fail in container builds.

The Hallway Dilemma

Another area where the specific measurement of how wide is a container home matters immensely is the hallway. IRC Section R311.6 requires hallways to be a minimum of 3 feet (36 inches) wide. If you design a hallway running alongside a bathroom, you have the exterior wall stack + the hallway width + the interior partition wall + the bathroom width. The math is unforgiving.

| Space Type | IRC Reference | Minimum Width Requirement |

|---|---|---|

| Habitable Rooms | R304.2 | 7 feet (84 inches) |

| Hallways | R311.6 | 3 feet (36 inches) |

| Egress Doors | R311.2 | 32 inches clear width |

Our plans address exactly how wide is a container home hallway by utilizing specific framing details that accommodate electrical systems without sacrificing the necessary inches for code compliance.

📖 View Full IRC Section R311.6 Text

IRC Section R311.6 – Hallways:

The width of a hallway shall be not less than 3 feet (914 mm).

Source: 2021 International Residential Code

The Professional Engineer’s Role

When you ask how wide is a container home, you are partly asking a structural question. To achieve a livable width, you often need to modify the container shell—cutting openings for windows, removing sections of corrugated steel for widening, or drilling through rails for utility runs. Each of these actions compromises the structural integrity of the ISO box.

This is where the Professional Engineer (PE) becomes essential. Unlike traditional stick framing, where prescriptive codes allow you to simply look up a header size in a table, shipping container modifications often fall outside of “conventional construction” limits. Your PE calculates the necessary reinforcement to ensure your home doesn’t buckle under snow loads or rack during high winds.

Engineering for Non-Conventional Elements

Because shipping containers are repurposed elements, most building departments classify them as “nonconventional” under the IRC. This classification triggers the requirement for an engineered design. Your PE will take our architectural plans and apply the specific calculations required for your local wind, snow, and seismic conditions.

Partnering with a Professional Engineer ensures your home meets all structural and safety standards for your specific location. PE review typically costs $2,000-$5,000 depending on project complexity and provides the expert certification your building department needs to issue a permit.

The International Code Council provides the framework for when this engineering is mandatory. Specifically, when a building element does not conform to the prescriptive tables of the code, an engineered design is required.

📖 View Full IRC Section R301.1.3 Text

IRC Section R301.1.3 – Engineered design:

Where a building of otherwise conventional construction contains structural elements exceeding the limits of Section R301 or otherwise not conforming to this code, these elements shall be designed in accordance with accepted engineering practice. The extent of such design need only demonstrate compliance of nonconventional elements with other applicable provisions and shall be compatible with the performance of the conventional framed system. Engineered design in accordance with the International Building Code is permitted for buildings and structures, and parts thereof, included in the scope of this code.

Source: 2021 International Residential Code

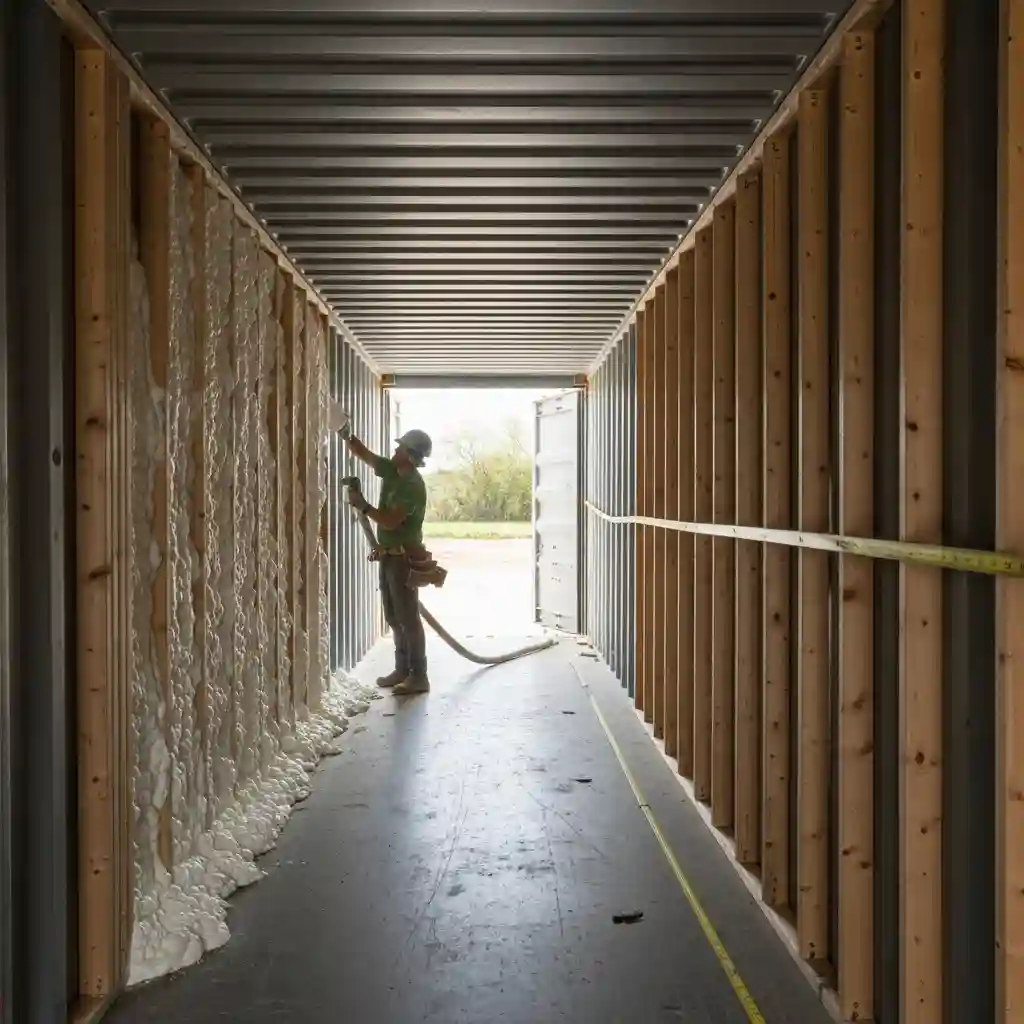

Insulation Strategies to Maximize Width

The battle for inches in a container home is often fought in the walls. To answer how wide is a container home interior effectively, you must select an insulation strategy that meets code requirements with the thinnest possible profile. The 2021 IRC has increased insulation requirements for many climate zones, making this challenge even more acute.

In many climates, simply stuffing fiberglass batts into a 2×4 wall is no longer sufficient to meet energy codes, nor is it space-efficient. To maximize your interior width, you must often utilize high-performance materials like closed-cell spray foam or continuous exterior insulation.

For detailed guidance on energy-efficient building strategies and material selection, the U.S. Department of Energy provides extensive resources on insulation performance and climate-specific recommendations.

Insulation Thickness vs. R-Value

The table below compares common insulation methods. Note how the “Wall Stack Depth” dictates your final living space. A thinner wall means a wider room.

| Insulation Method | Approx. R-Value per Inch | Typical Wall Depth (R-13) | Impact on Width |

|---|---|---|---|

| Closed Cell Spray Foam | R-6.0 – R-7.0 | ~2.0 inches | Least Intrusive |

| Rigid Foam Board (XPS) | R-5.0 | ~2.6 inches | Moderate |

| Open Cell Spray Foam | R-3.5 – R-4.0 | ~3.5 inches | High |

| Fiberglass Batts | R-3.1 – R-3.4 | ~4.0 inches | Highest |

The Continuous Insulation Challenge

The 2021 IRC Table N1102.1.3 introduces stricter requirements. For example, in Climate Zone 4 (except Marine), wood frame walls require “20 + 5” (R-20 cavity insulation plus R-5 continuous insulation) or “13 + 10ci” (R-13 cavity plus R-10 continuous). This “continuous insulation” requirement implies adding layers outside the studs or container shell, which can complicate your exterior width calculations but save interior space.

Meeting these R-values inside an 8-foot box requires careful engineering. If you are forced to build thick walls to meet R-values, your interior width could shrink below the 7-foot habitable room minimum.

📖 View IRC Table N1102.1.3 (R402.1.3) Requirements

IRC Table N1102.1.3 (R402.1.3) – Insulation Minimum R-Values:

Climate Zone 3: Wood Frame Wall R-Value: 20 or 13 + 5ci or 0 + 15

Climate Zone 4 except Marine: Wood Frame Wall R-Value: 30 or 20 + 5 or 13 + 10ci or 0 + 15

Note: “13 + 5ci” means R-13 cavity insulation plus R-5 continuous insulation.

Source: 2021 International Residential Code

Furniture & Layout Planning: Living in 7 Feet

Once you understand how wide is a container home—really only about 7’4″ to 7’8″ depending on your insulation—you realize that standard furniture placement requires strategy. A typical queen mattress is 60 inches wide. If your room is 88 inches wide (7’4″), you have exactly 14 inches of clearance on each side of the bed. This is tight, but livable.

The layout challenge extends to egress windows. To meet code, you need specific clear opening widths. When you cut a hole in a container wall for an egress window, you must frame it out. If your walls are already thick with insulation, deep window wells can reduce the perceived width of the room even further.

Egress Windows & Width Constraints

It is not just about the furniture fitting; it is about you fitting through the window in an emergency. The IRC mandates that every sleeping room must have an emergency escape opening. This opening has minimum width requirements that must be met after the window installation. When calculating how wide is a container home bedroom, ensure your furniture layout does not block access to this critical 20-inch wide escape route.

📖 View Full IRC Section R310.2.2 Text

IRC Section R310.2.2 – Minimum dimensions:

The minimum net clear opening height dimension shall be 24 inches (610 mm). The minimum net clear opening width dimension shall be 20 inches (508 mm).

Source: 2021 International Residential Code

The “Built-In” Solution

To maximize the feeling of space when asking how wide is a container home, built-in furniture is the answer. By attaching cabinetry directly to the wall studs (or even recessing it into the wall cavity if engineered correctly), you can save 2-3 inches of depth compared to freestanding units. Our plans often feature integrated storage solutions that utilize the “corrugation void” space where possible.

Expert Tips & Key Takeaways

Answering how wide is a container home is a dynamic process that involves balancing energy efficiency, structural integrity, and livability. By planning your wall stack down to the millimeter, you can create a home that feels surprisingly spacious.

Essential Points Summary

- Wall Stack Matters: Never assume 8 feet. Always calculate: 8’0″ – (Steel + Framing + Insulation + Drywall x 2). Your real width is likely between 7’2″ and 7’6″.

- R-Value vs. Space: Closed-cell spray foam is the most space-efficient way to meet the R-20+ requirements of modern codes without sacrificing interior width.

- IRC Minimums are Non-Negotiable: Habitable rooms must be at least 7 feet wide. Hallways must be 3 feet wide. Do not build walls that violate these rules.

- Engineering is Required: Modifying the container width (by joining containers or removing walls) requires a Professional Engineer (PE) to ensure the structure remains sound.

- Plan for Plumbing: Wet walls are thicker (usually 6 inches). Place them on interior partitions rather than exterior walls to preserve maximum building width.

With precise planning and professional support, the constraints of a shipping container can drive creative, efficient design. Understanding exactly how wide is a container home is the first step toward a successful build.

Ready to Start Your Container Home Project?

Explore our collection of comprehensive container home plans designed to align with 2021 IRC and IBC building code standards. Each plan includes complete architectural drawings, structural details, electrical layouts, plumbing systems, and beautiful 3D visualizations—everything your Professional Engineer needs for efficient review.

Browse Complete Plan Collection →Need Plan Modification? If you find a plan you love but need to adjust it for your local climate or personal needs—such as moving a window or adding a door—our team can help. We offer a professional plan modification service after purchase. Simply contact us with your modification needs, and we’ll provide a personalized quote.

⚖️ Professional Engineering & Plan Documentation Disclaimer

Important: Our plans are permit-ready but require review and stamping by a local licensed Professional Engineer (PE) in your jurisdiction. Final approval is subject to local building codes and regulations. We recommend consulting your local building department to verify all requirements.

Refund Policy: Due to the digital nature of our plans, all sales are final. Please review our Refund Policy for details.