The Ultimate Commercial Container Building Guide: Master IBC Codes for Success

From Pop-Up Shops to Permanent Offices: Navigating the 2021 International Building Code for Commercial Container Building Projects

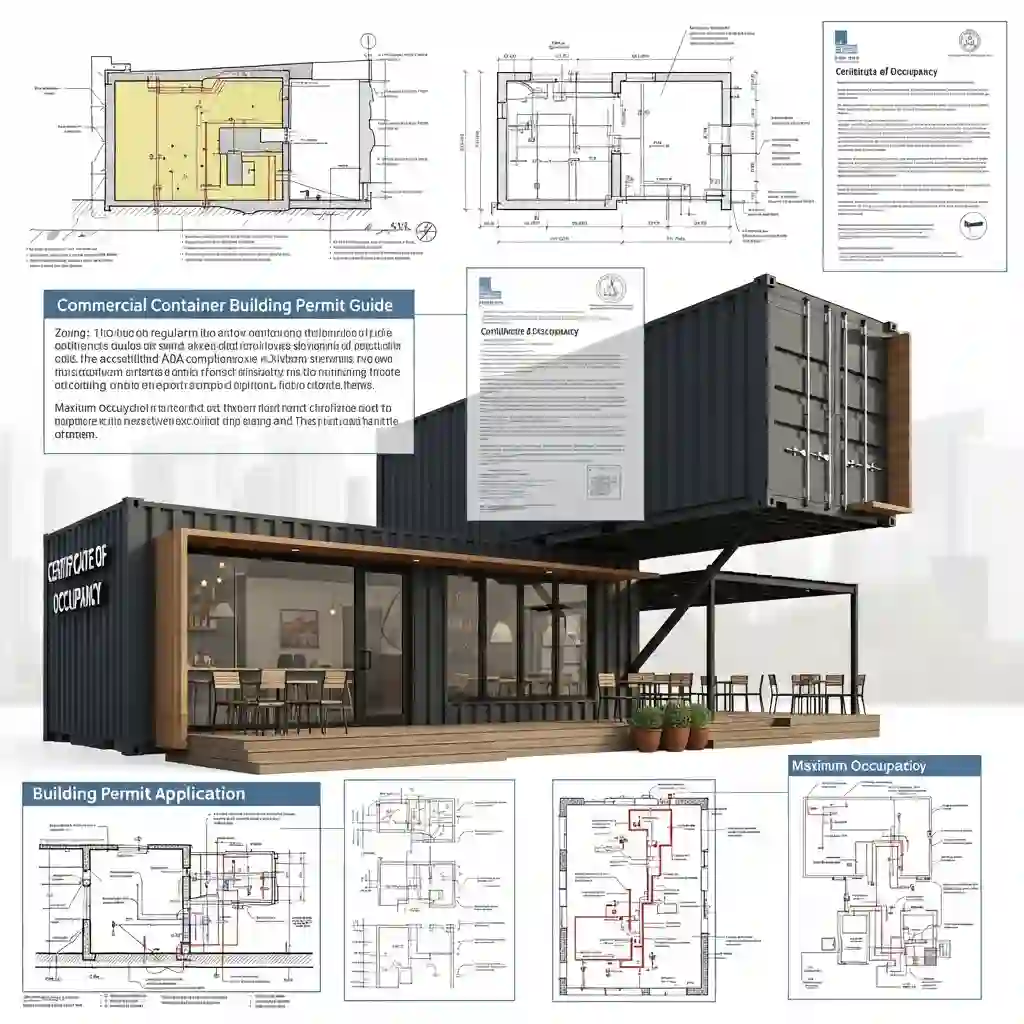

You have a vision: a sleek, industrial-modern coffee shop made from a 20ft High Cube, or perhaps a multi-unit retail complex constructed from stacked 40ft containers. The aesthetic is undeniable, the sustainability story is compelling, and the speed to market is attractive. However, as a Senior Structural Engineer, I must be the one to separate the Pinterest dream from the regulatory reality. Building a commercial container building involves a completely different set of rules than a backyard ADU.

When you shift from residential to a commercial container building, you move from the International Residential Code (IRC) to the International Building Code (IBC). This isn’t just an acronym change; it is a fundamental shift in safety philosophy. The IBC assumes higher occupant loads, public access, and diverse uses, triggering rigorous requirements for accessibility, fire suppression, and structural integrity.

In this guide, we will deconstruct the 2021 IBC provisions that specifically target shipping containers—yes, they are now officially codified in Section 3115—and walk you through the engineering hurdles of converting a steel box into a legal business. Let’s ensure your commercial container building project starts on a code-compliant foundation.

1. The Game Changer: IBC 2021 Section 3115

For years, building officials treated containers as “alternative materials” under Section 104.11, requiring exhausting justification for every project. The 2021 IBC changed everything by introducing Section 3115: Intermodal Shipping Containers. This section provides a prescriptive path to compliance, meaning if you follow the rules, the building official should approve your commercial container building.

According to IBC Section 3115.3, you must verify the existing data plate on the container. This plate contains critical engineering data required for your commercial container building permit application.

📖 View IBC 3115.3 Data Plate Requirements

3115.3 Intermodal shipping container information. Intermodal shipping containers shall bear an existing data plate containing the following information as required by ISO 6346 and verified by an approved agency:

- Manufacturer’s name or identification number.

- Date manufactured.

- Safety approval number.

- Identification number.

- Maximum operating gross mass or weight (kg) (lbs).

- Allowable stacking load for 1.8G (kg) (lbs).

- Transverse racking test force (Newtons).

- Valid maintenance examination date.

If your containers are missing these plates, or if they have been modified heavily before arriving at your site, we may need to perform material testing to establish the steel grade and composition (IBC 3115.8.4.1). This is expensive. Always buy containers with intact data plates for any commercial container building project.

2. Occupancy Classification: Who is Inside?

Before we calculate a single beam, we must define the “Use and Occupancy” (Chapter 3 of the IBC). This classification dictates your fire ratings, number of exits, and allowable area. A commercial container building typically falls into one of these categories:

| Occupancy Group | Typical Uses | Critical Code Constraints |

|---|---|---|

| Group B (Business) | Professional offices, banks, barber shops, animal hospitals. | Generally lower hazard. Occupant load factor: 150 gross sq. ft. per person. |

| Group M (Mercantile) | Retail stores, markets, sales rooms. | Moderate hazard. High merchandise density. Occupant load factor: 60 gross sq. ft. per person. |

| Group A-2 (Assembly) | Restaurants, cafes, bars, banquet halls. | High hazard due to density and alcohol/food. Requires sprinklers often. Occupant load factor: 15 net sq. ft. per person (tables/chairs). |

| Group S-1 (Storage) | Warehouses, moderate hazard storage. | Often used for inventory. Lower occupant load, but higher fire load depending on contents. |

3. Structural Integrity & The “Simplified” Design Method

Commercial buildings endure heavier loads than residential homes. The IBC requires us to prove the structure can handle wind, snow, and seismic forces. Fortunately, IBC Section 3115.8.5 introduces a “Simplified structural design” method for a single-unit commercial container building.

The Single-Unit Shortcut

If your commercial container building consists of a single container (e.g., a drive-thru coffee stand), and you do not cut the top or bottom rails, we can use a simplified approach. We treat the corrugated steel walls as shear walls with specific allowable values.

📖 View Table 3115.8.5.3 Allowable Shear Values

ALLOWABLE SHEAR VALUES (PLF)

Based on ISO 1496-1 and reduced by safety factor of 5.

- 20ft Container (1CC, 1C, 1CX):

- Side Wall: 168 plf

- 40ft Container (1AAA, 1AA, 1A, 1AX):

- Side Wall: 84 plf

Note: To use these values, limitations apply (e.g., Seismic Design Category A-D, no notches in rails).

However, most commercial container building projects involve modifications. You want large glass storefronts, service windows, and open floor plans. As soon as we cut a sidewall, we compromise the container’s monocoque strength.

IBC 3115.8.4 requires a detailed structural analysis for modified containers. This ensures that the new steel lintels and columns restore the strength lost by cutting the corrugation.

4. Fire Safety & Property Lines

In commercial container building construction, where you build on the lot matters immensely. This is governed by Fire Separation Distance (Table 602). Steel containers are technically non-combustible, but if you insulate them with spray foam or wood framing, they become “combustible” assemblies in the eyes of the code.

The Exterior Wall Problem

If you place your commercial container building close to a property line (usually within 10 to 30 feet), the exterior wall must have a fire-resistance rating (1-hour or 2-hour). While the steel skin resists fire, it conducts heat rapidly, potentially igniting materials on the other side.

- 0-5 Feet from Lot Line: Usually not permitted for openings (windows). Wall must be rated (e.g., layers of Type X Gypsum).

- 5-10 Feet from Lot Line: Limited percentage of openings allowed. Rating still required.

- 10-30 Feet from Lot Line: More flexibility, but rating depends on Occupancy Group.

Section 1402.5 of the IBC specifically addresses water-resistive barriers on Types I-IV construction. If you are building a Type IIB (unprotected non-combustible) commercial container building, we must ensure your exterior cladding and insulation don’t compromise the non-combustible nature of the steel structure.

5. Accessibility: ADA Compliance in a 8ft Box

This is the number one reason commercial container building projects fail plan review: Accessibility (IBC Chapter 11). Federal law and building codes require commercial spaces to be accessible to individuals with disabilities, per the ADA Standards for Accessible Design.

The Geometry Challenge

A standard shipping container is roughly 8 feet wide (exterior). The interior width, after framing and insulation, is often ~7′ 4″, which presents a challenge for a code-compliant commercial container building.

- 360-Degree Turn: An accessible bathroom requires a 60-inch (5 ft) turning circle. That eats up nearly the entire width of the container.

- Door Widths: IBC 1010.1.1 requires a minimum clear opening width of 32 inches. Standard container cargo doors do not meet egress requirements; you must cut in compliant man-doors.

- Ramps: If your commercial container building sits on a chassis or foundation, the floor is 6-12+ inches above grade. IBC 1012 requires a ramp slope of 1:12. A 12-inch rise requires a 12-foot long ramp.

6. The Commercial Permitting Roadmap

The commercial container building permitting process is a multi-stage journey. Unlike residential, you will likely need a Design Professional (Architect or Engineer) of Record.

Step 1: Zoning Review

Before looking at the building code, check local zoning. Is “container” listed as a prohibited material? Are there overlay districts requiring masonry facades? Address this first.

Step 2: The Code Analysis Sheet

Your plan set must include a dedicated sheet detailing:

- Applicable Code: IBC 2021 (or local variant).

- Occupancy Group: (e.g., Group B, Group M).

- Construction Type: (e.g., Type IIB or Type VB).

- Occupant Load Calculation: (Gross vs. Net floor area).

- Allowable Area & Height: Based on IBC Chapter 5.

Step 3: MEP Engineering

Commercial Mechanical, Electrical, and Plumbing (MEP) codes are stricter for a commercial container building. You may need fresh air intake calculations (ASHRAE 62.1) and specific energy conservation measures (IECC) for lighting and insulation.

Launch Your Business Fast

Don’t let the code book slow you down. Our Commercial Plans are pre-engineered to IBC 2021 standards.

Browse Commercial PlansIf you find a plan you love but need to adjust it for your local climate or personal needs—such as moving a window or adding a door—our team can help. We offer a professional plan modification service after purchase. Just contact us for a personalized quote!

Disclaimer: The information provided in this commercial container building guide is for educational purposes only and does not constitute professional engineering or legal advice. Building codes (IBC, IRC) vary by location and are subject to local amendments. Always consult with your local building department and a licensed professional engineer or architect before starting any construction project. PermitContainerHomes.com is not responsible for project rejections or code violations based on this content.