High Cube vs. Standard Container: The Ultimate Guide to Ceiling Height & Codes

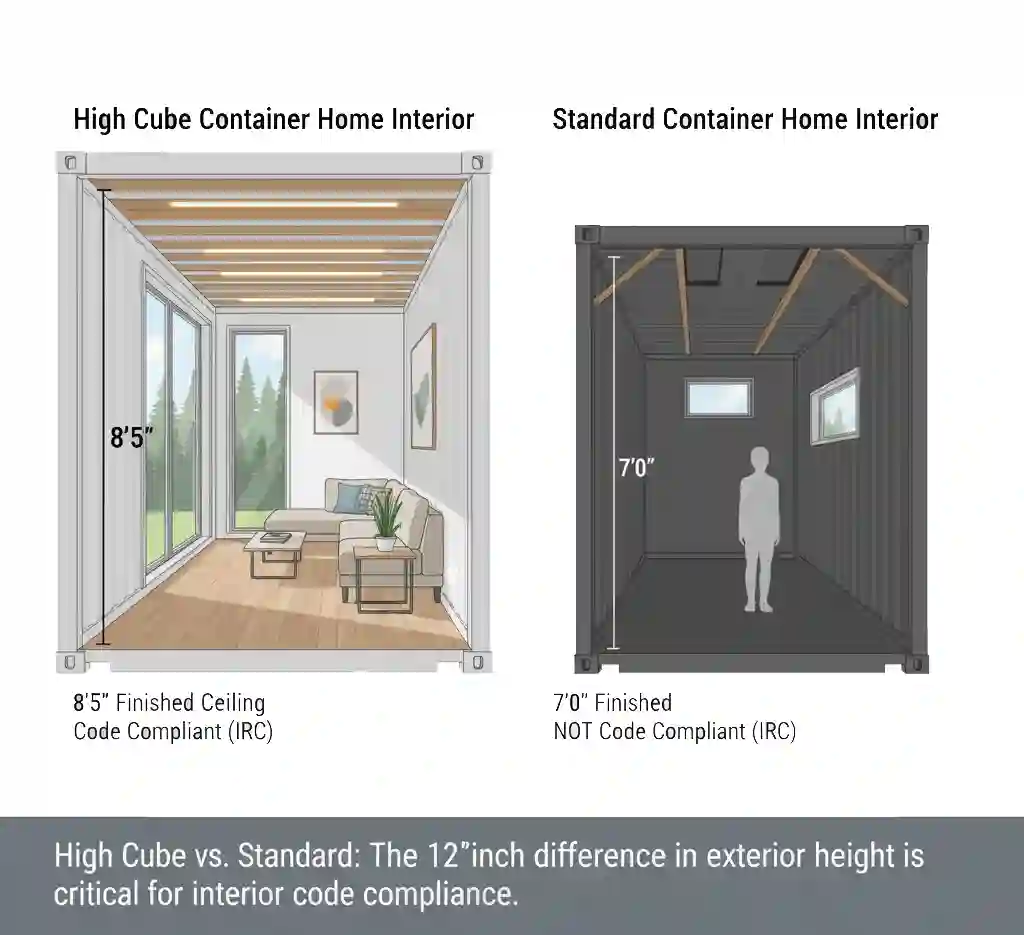

Making the right choice isn’t just about comfort—it’s about building code compliance. We explain why a high cube container home is almost always the correct, permit-ready choice.

Welcome to your complete guide on one of the most critical decisions you will make for your container home build: choosing between a Standard container and a High Cube container. It may seem like a simple choice—after all, it’s just one foot of height—but this single dimension is arguably the most important factor in determining whether your project is a comfortable, legal, and permit-approved success, or a costly, claustrophobic failure.

Many aspiring builders are tempted by the slightly lower price of standard containers, only to discover—often during a failed framing inspection—that it’s impossible to meet legal ceiling height requirements after adding necessary insulation, flooring, and utilities. This guide is here to help you avoid that expensive mistake.

We will dive deep into the technical specifications, building code mandates, and practical design implications of each choice. Our goal, as always, is to be your humble and professional partner, guiding you toward a safe, successful build. By the end of this guide, you will understand exactly why a high cube container home is the foundation of nearly every successful, code-compliant build in North America.

Defining the Difference: A Tale of 12 Inches

At their core, both Standard (STD) and High Cube (HC) shipping containers are incredibly strong, weather-resistant Corten steel boxes built to strict ISO (International Organization for Standardization) standards. They were designed to be stacked, shipped, and endure the harshest conditions on earth. This durability is what makes them such a fantastic building material. The only significant difference is their exterior height.

The Standard (STD) Container: The Original Workhorse

A Standard container, often called a “general purpose” or “dry van” container, has a fixed exterior height of 8 feet, 6 inches (8′ 6″ or 2.59m). After accounting for the steel floor and corrugated roof structure, a brand-new container has an interior ceiling height of approximately 7 feet, 10 inches (7′ 10″ or 2.39m). This is the “clear” height before you add any flooring, insulation, or ceiling finishes.

- Exterior Height: 8′ 6″ (2.59m)

- Interior Height (New): ~7′ 10″ (2.39m)

- Common Uses: Global freight, storage, construction site offices.

- Appeal for Building: They are widely available and often slightly cheaper than High Cubes.

The High Cube (HC) Container: The Builder’s Choice

A High Cube container is identical in length, width, and strength to a standard container, but it has an exterior height of 9 feet, 6 inches (9′ 6″ or 2.89m). That extra 12 inches of exterior height translates directly to the inside, giving you an initial interior ceiling height of approximately 8 feet, 10 inches (8′ 10″ or 2.69m). This is the container that forms the basis of a proper high cube container home.

- Exterior Height: 9′ 6″ (2.89m)

- Interior Height (New): ~8′ 10″ (2.69m)

- Common Uses: Global freight (for oversize cargo), and increasingly, container architecture.

- Appeal for Building: That “extra” foot of space is not a luxury; it is the critical component that allows for code-compliant insulation, utilities, and finished ceiling heights.

Visual Comparison: Standard vs. High Cube Containers

Here is a simple breakdown of the dimensional differences. Note that interior dimensions can vary slightly based on the manufacturer and the “wall stack” (the thickness of the corrugated steel), but these are industry-standard averages.

| Dimension | 40′ Standard Container (STD) | 40′ High Cube Container (HC) |

|---|---|---|

| Exterior Height | 8′ 6″ (2.59m) | 9′ 6″ (2.89m) |

| Exterior Length | 40′ 0″ (12.19m) | 40′ 0″ (12.19m) |

| Exterior Width | 8′ 0″ (2.44m) | 8′ 0″ (2.44m) |

| Interior Height (Approx.) | ~7′ 10″ (94 inches) | ~8′ 10″ (106 inches) |

| Interior Length (Approx.) | 39′ 5″ (12.03m) | 39′ 5″ (12.03m) |

| Interior Width (Approx.) | 7′ 8.5″ (2.35m) | 7′ 8.5″ (2.35m) |

| Cubic Volume (Approx.) | 2,385 cu ft | 2,690 cu ft |

How to Identify a High Cube Container

It can be difficult to tell the difference from a distance, but there are two clear indicators to look for when you are inspecting a container for purchase:

- Height Markings: The container’s data plate (on the doors) will list the exterior height. A High Cube will be marked as 2.89m or 9′ 6″.

- Striped Sticker: Most High Cube containers have a yellow and black striped warning sticker on the top rail at all four corners. This is to warn crane operators and depots that it is an “overheight” container.

The Code is King: Why Building Codes Mandate a Taller Ceiling

This is the most important section of this guide. Your local building department’s primary mission is to ensure your home is safe and habitable. To do this, they adopt and enforce a set of rules, most commonly the International Residential Code (IRC). These codes are not suggestions; they are the law. And the IRC is very clear about ceiling heights.

We’re not sharing this to intimidate you, but to empower you. Knowing these rules is the first step to a smooth permit process. These codes are published by the International Code Council (ICC), a high-authority organization dedicated to building safety.

Understanding IRC Section R305.1: The “Minimum Ceiling Height” Rule

The 2018 and 2021 versions of the IRC—which are the basis for building codes in most US states—contain a section titled R305.1 Minimum Height. This section states:

“Habitable space, hallways, bathrooms, toilet compartments, laundry rooms and portions of basements containing these spaces shall have a ceiling height of not less than 7 feet (2134 mm).”

This is the magic number: 7 feet, 0 inches (84 inches). This applies to your “finished” ceiling—that is, the distance from your finished floor (like your laminate or tile) to your finished ceiling (your drywall or wood paneling). This rule applies to bedrooms, living rooms, and kitchens. This is a non-negotiable life-safety and habitability standard.

Are There Any Exceptions?

Yes, the code provides a few minor exceptions, which are important to understand:

- Bathrooms: Bathrooms, toilet compartments, and laundry rooms can have a minimum height of 6 feet, 8 inches (80 inches). This also applies to the area over and around the fixtures (like a shower or toilet).

- Beams and Girders: Beams and girders spaced at least 4 feet apart can project down to 6 feet, 6 inches (78 inches) from the finished floor.

- Sloped Ceilings: In rooms with sloped ceilings (not common in container homes unless you add a roof), at least 50% of the required floor area must have a ceiling height of 7 feet.

The key takeaway is that for all the main living areas of your home, you must be able to stand on your finished floor and measure at least 84 inches to the finished ceiling. As we are about to see, this is where the 12-inch difference between a Standard and High Cube container becomes the difference between legal and illegal.

The “Big Squeeze”: Why Standard Containers Fail Inspection

Let’s do the math. This is what we call the “stack-up,” and it’s where the dream of using a cheaper Standard container meets the hard reality of building codes. You cannot simply lay a rug on the container floor and paint the steel ceiling. To create a home that is legal, comfortable, and energy-efficient, you must add a floor assembly and a ceiling assembly.

Your finished home must have:

- A Floor Assembly: This includes insulation (often rigid foam or spray foam underneath), framing (sleepers or “floating” 2x4s), a subfloor (like plywood), and your finished flooring (LVP, tile, hardwood, etc.).

- A Ceiling Assembly: This includes insulation (spray foam is most common), framing (wood or steel studs), and your finished ceiling (like drywall or shiplap). This assembly must also contain all your “hidden” infrastructure: electrical wires, junction boxes for lights, and potentially plumbing lines or HVAC ducts.

Let’s see what happens when we try to fit this into a Standard container.

The Math That Fails: A Standard Container Stack-Up

We are starting with a best-case scenario: a brand-new Standard container with a clear interior height of 7 feet, 10 inches (94 inches).

Step 1: The Required Floor Assembly

To have a warm, comfortable floor that isn’t a freezing cold steel plate, you need an insulated assembly. A very common method is:

- Wood Sleepers (2×3 or 2×4 laid flat): -1.5 inches

- Rigid Foam Insulation (between sleepers): (Does not add to height loss)

- Plywood or OSB Subfloor: -0.75 inches

- Underlayment & Finished Floor (e.g., LVP): -0.5 inches

Total Floor Height Loss (Minimum): 2.75 inches

Step 2: The Required Ceiling Assembly

To meet modern energy codes (which we detail in our container home insulation guide) and to run wiring, you need a ceiling assembly. A typical setup includes:

- Closed-Cell Spray Foam (High R-value): -3.0 inches (This is a common depth for R-21)

- Wood or Steel Furring Strips (to attach drywall): -1.5 inches

- Recessed Light “Pancake” Boxes: (Must fit within this 1.5″ space)

- Finished Ceiling (1/2″ Drywall): -0.5 inches

Total Ceiling Height Loss (Minimum): 5.0 inches

Step 3: The Final, Failed Calculation

Let’s add it all up:

| Item | Dimension |

|---|---|

| Initial Interior Height (Standard) | 94.0 inches |

| Minus: Floor Assembly Loss | -2.75 inches |

| Minus: Ceiling Assembly Loss | -5.0 inches |

| Final Finished Ceiling Height | 86.25 inches (7 feet, 2.25 inches) |

| IRC Minimum Requirement | 84.0 inches (7 feet, 0 inches) |

You might look at this and think, “Great! I have 2.25 inches to spare!” This is the trap.

Where It All Goes Wrong: The “Gotchas”

That 2.25-inch buffer will disappear instantly:

- Used Containers: The 94″ height is for a new container. A used one, with floor dings and roof dents, will have less.

- Slightly Thicker Flooring: Want tile in the bathroom? The mortar bed and tile add up to 1 inch, not 0.5. Your ceiling height is now 85.75″.

- Uneven Floors: The original container floor may have a slight bow. Your 1.5″ sleepers may need to be 2″ in some places to level it. You’re now at 85.25″.

- The HVAC “Gotcha”: Where are you putting your mini-split head unit? It hangs below the finished ceiling, projecting into the room. It must still have 6′ 8″ of clearance below it, which is nearly impossible.

- The Beam “Gotcha”: If you combine two containers, you must add a large steel beam where you cut the walls out. This beam will hang below your 86.25″ ceiling. Per code (R305.1), this beam can’t be lower than 78 inches (6′ 6″). This gives you only 8.25 inches for one of the largest structural elements in your home, which is often not enough, forcing you to compromise the entire design.

A Standard container forces you to build with zero margin for error. Any small change, any slightly thicker material, any minor structural need, and your project is no longer code-compliant. An inspector with a tape measure can (and will) fail your project, forcing a “Stop Work” order until you present a costly, engineered solution.

The High Cube Solution: Building Your High Cube Container Home with Confidence

Now, let’s run the exact same calculation, but starting with a High Cube container. This simple change transforms the build from a stressful compromise into a confident, straightforward process.

This is why we, and virtually all professional container home designers, base our plans exclusively on High Cube containers. This is the key to building a high cube container home that feels like a real home.

The Math That Works: A High Cube Container Stack-Up

We are starting with a clear interior height of 8 feet, 10 inches (106 inches).

Step 1: The Floor Assembly (Same as Before)

We use the same comfortable, insulated floor assembly.

Total Floor Height Loss (Minimum): 2.75 inches

Step 2: The Ceiling Assembly (With “Breathing Room”)

Now we are not constrained. We can use a better ceiling assembly that easily accommodates utilities and higher insulation values.

- Closed-Cell Spray Foam (Better R-Value): -4.0 inches (Achieving R-28)

- 2×4 Framing (for strength and utility space): -3.5 inches

- Finished Ceiling (5/8″ Drywall): -0.625 inches

Total Ceiling Height Loss (Comfortable): 8.125 inches

This may seem like a lot, but this 8-inch “service cavity” is a builder’s dream. It allows for full-sized recessed lights, all plumbing vents, electrical conduits, and even small HVAC ducts to be run easily, without compromising the structure or creating “drops” in the ceiling.

Step 3: The Final, Confident Calculation

Let’s add up the new math:

| Item | Dimension |

|---|---|

| Initial Interior Height (High Cube) | 106.0 inches |

| Minus: Floor Assembly Loss | -2.75 inches |

| Minus: Ceiling Assembly Loss | -8.125 inches |

| Final Finished Ceiling Height | 95.125 inches (7 feet, 11.125 inches) |

| IRC Minimum Requirement | 84.0 inches (7 feet, 0 inches) |

The Overwhelming Benefits of a High Cube

This is a night-and-day difference. Instead of scraping by with 2.25 inches of “hope,” you now have over 11 inches of buffer. This is not just “extra”; it is essential.

This 11-inch buffer allows you to:

- Pass Inspection Easily: Your inspector measures an ~8-foot ceiling. It’s an instant pass.

- Install Ceiling Fans: You now have ample height to install a standard ceiling fan while maintaining more than 7 feet of clearance for safety.

- Use Any Flooring: Want thick, beautiful tile? No problem. It won’t put you at risk of failing code.

- Run Utilities: Your electrician and plumber will thank you. They can run pipes and wires without complex, “creative” (and non-compliant) workarounds.

- Install Beams: That large steel beam needed to connect two containers? It can now hang 10-12 inches below the ceiling and still be well above the 6′ 6″ code minimum, making it an intentional design feature instead of a head-knocking hazard.

- Meet Energy Codes: You have the space to add extra insulation to meet strict energy standards, such as those from ENERGY STAR, saving you money on heating and cooling for the life of your home.

Livability and Design: Beyond the Building Code

Building a home isn’t just about passing inspection—it’s about creating a space you love to live in. The 8-foot-wide interior of a container is already a design challenge. A low ceiling compounds this, creating a “tunnel” or “tube” effect that can feel claustrophobic and dark. A high cube container home fundamentally solves this problem.

Psychological Comfort: Avoiding “The Tunnel”

The extra vertical space of a High Cube draws the eye upward. This simple architectural trick makes the entire space feel wider, brighter, and more open. A finished 8-foot (or higher) ceiling feels just like a standard site-built home, removing any “container” stigma and replacing it with a sense of comfort and spaciousness. This psychological benefit cannot be overstated.

Practical Design Advantages of a Taller Ceiling

That extra foot of height unlocks a world of interior design possibilities that are simply impossible in a standard container.

Ceiling Fans and Lighting Fixtures

- Standard Container: You are restricted to flat, flush-mount “pancake” lights. A ceiling fan is a safety hazard and likely illegal, as the blades would be too close to the 7-foot minimum clearance.

- High Cube Container: You can install beautiful, modern ceiling fans to circulate air (critical in a narrow home). You can use stunning pendant lights over your kitchen island or dining table. You have room for track lighting, chandeliers, and proper recessed “can” lights.

Vertical Storage and Cabinetry

- Standard Container: In a kitchen, you can’t use standard 36-inch or 42-inch upper cabinets; they would be too low or hit the ceiling. You are forced to use short, custom cabinets, sacrificing huge amounts of storage.

- High Cube Container: You can use standard, off-the-shelf kitchen cabinets. This allows for full-height pantries, stacked upper cabinets (for seasonal items), and a proper range hood. In bedrooms, you can have floor-to-ceiling closets.

Lofts, Bunk Beds, and Murphy Beds

- Standard Container: A sleeping loft or a bunk bed is physically impossible. A vertical-mount Murphy bed may not even have room to pivot down.

- High Cube Container: This is a game-changer for smaller plans. A High Cube makes it possible to build a code-compliant sleeping loft (with a 6′ 8″ ceiling in the bathroom below, for example). It’s perfect for our 1-bedroom and ADU plans, allowing you to build bunk beds for kids or a guest loft.

Windows and Doors

- Standard Container: A standard 6′ 8″ door will look awkwardly tall, with the trim nearly touching the finished ceiling.

- High Cube Container: You can use standard 6′ 8″ doors and they look proportional. Even better, you have room above the doors and windows to add transom windows, a classic architectural feature that floods the narrow home with natural light from high on the wall, enhancing privacy and brightness.

Cost, Availability, and Logistics: A True Value Comparison

This is the point where many people hesitate. “But aren’t High Cube containers more expensive?” Yes, they are. But the small upfront cost is an investment that saves you multiples of that cost down the line. Choosing a Standard container to “save money” is a classic example of being “penny wise and pound foolish.”

Upfront Purchase Price

A used 40′ High Cube container might cost $1,000 – $2,000 more than a used 40′ Standard container. Let’s look at a rough comparison (Note: prices vary dramatically by location and market conditions).

| Container Type | Average Used “WWT” Cost | Average “One-Trip” Cost |

|---|---|---|

| 40′ Standard (STD) | $2,000 – $3,500 | $4,000 – $5,500 |

| 40′ High Cube (HC) | $3,000 – $5,000 | $5,000 – $7,000 |

Looking at this, you might see a $1,500 difference and be tempted to take the Standard. Here is why that is the worst financial decision you can make in your build.

The “Hidden Costs” of a Standard Container

That $1,500 you “saved” will be spent (and then some) on these “hidden” costs:

- Cost of Failed Inspections: A “Stop Work” order from a building inspector. You will have to pay an engineer to draft a “fix,” which may involve tearing out your finished work. Potential Cost: $5,000 – $15,000

- Cost of Exotic Insulation: To get the required R-value in a tiny 2-inch space, you may have to use extremely expensive Vacuum Insulated Panels (VIPs) or aerogel. Potential Cost: $3,000 – $7,000

- Cost of Customization: You cannot use standard doors, cabinets, or shower inserts. Everything must be custom-ordered or site-built, which is far more expensive than off-the-shelf components. Potential Cost: $2,000 – $6,000

- Cost of Complex Engineering: If you try to sink the floor (a common “fix” people suggest online), you are cutting out the primary structural diaphragm of the container. This requires a massive engineering review and complex steel fabrication. Potential Cost: $4,000 – $8,000

- Cost of Lost Resale Value: A dark, claustrophobic, and questionably-legal home will sell for far less than a bright, open, and fully-compliant high cube container home. Potential Cost: $20,000+

That $1,500 you “saved” upfront has now cost you over $20,000 in fixes, expensive materials, and lost equity.

The Verdict: The extra $1,500 for a High Cube container is the single best investment you can make in your project. It is not an expense; it is the “insurance policy” that ensures your build is legal, comfortable, and valuable.

Availability and Transportation

Are High Cube Containers Hard to Find?

Not at all. The 40-foot High Cube (40′ HC) is an extremely common container in the global shipping fleet and is readily available from any reputable container reseller. Our 40ft container home plans are based on this common type.

The 20-foot High Cube (20′ HC) is rarer. They are not as common in the shipping fleet. However, most container modification companies build them by taking a 40′ HC, cutting it in half, and welding a new steel end wall on. This is a very standard process. All our plans specify the exact container type required, removing any guesswork for you.

Transportation and Placement

The delivery to your site is virtually identical. Both containers are delivered on the same type of truck (tilt-bed or flatbed). The only difference is that a High Cube on a trailer may have a total height of 13′ 6″ to 14′ 6″. This is a standard height for commercial trucks, but it does mean you need to double-check your delivery route for any low bridges or tree limbs. This is a normal part of container home site preparation.

Niche Cases: When Could a Standard Container Ever Be Used?

We believe in being transparent, so are there any situations where a standard container is acceptable? Yes, but almost never for a primary dwelling.

We strongly advise against using Standard containers for any permitted, habitable space.

However, you might see them used for:

- Sheds or Workshops: If the structure is “non-habitable” (no sleeping, no kitchen) and is under your local jurisdiction’s size limit for permits (e.g., under 200 sq ft), you could use a standard container as a tool shed.

- Non-Insulated Structures: In a very mild climate (like parts of Hawaii) where you might build a structure with no insulation and just paint the interior walls, you might have enough height. This is still risky, as the steel will radiate heat and cold, and you have no space for wiring.

- Garages or Basements: A standard container could potentially be used as a garage level (though 8′ wide is very tight for car doors) or as a “walk-out basement” storage level below a High Cube container home. This adds complexity to the foundation design and engineering.

For 99% of home-building projects, these exceptions do not apply. The High Cube is the only correct choice.

How Our Permit-Ready Plans Solve This Problem for You

We understand that this is a lot of technical information. The good news is that we have already done all this work for you. Our entire mission at PermitContainerhomes.com is to remove the guesswork and risk from your build.

We Specify the Right Container, Every Time

Every single one of our permit-ready home plans is designed from the ground up using High Cube containers. This is not an add-on or an option; it is fundamental to our designs.

When you get a plan set from us, the cover sheet and specifications page clearly state “DESIGN BASED ON 9′ 6″ HIGH CUBE CONTAINER.” The floor plans, electrical plans, and, most importantly, the building sections, all show the math. They detail the floor and ceiling assemblies and clearly label a finished, code-compliant ceiling height (e.g., “FINISHED CEILING HEIGHT: 8′-0″”).

Why This is Your Key to Permit Approval

This single design choice solves two of your biggest problems:

- For Your Permit Office: When the plan reviewer sees “High Cube Container” and a building section showing a finished 8-foot ceiling, they can immediately check the box for IRC R305.1. It removes a major red flag and builds instant trust that your plans are professional and compliant. It’s a key part of our strategy for navigating container home building codes.

- For Your Builder: Your contractor isn’t left guessing. They don’t have to “invent” a risky, non-compliant assembly on the fly. The plans give them the exact material stack-up, leading to accurate bids, faster construction, and no failed inspections.

A Note on Plan Modifications

We’ve designed all our plans to maximize the space and comfort of a high cube container home. We’re confident you’ll love the open, airy feel. But we also know that every build is unique. If you find a plan you love but need to move a window, shift a door, or reconfigure a non-structural wall, we’re here to help. After purchase, we offer a plan modification service. Just contact us for a quote, and our team can help you get those custom tweaks just right.

❓ Frequently Asked Questions

Is a high cube container home always better than a standard?

For a habitable, code-compliant dwelling in the United States, yes, 100% of the time. The extra foot of height is essential for installing proper insulation, utilities, and flooring while still meeting the 7-foot minimum finished ceiling height required by the International Residential Code (IRC).

Can’t I just use a standard container and sink the floor?

You can, but it is an extremely complex and expensive modification. It involves cutting out the container’s entire original steel floor and C-channel supports, welding in a new, lower steel frame, and fabricating a new floor. This requires significant engineering approval (as it alters the container’s core structure) and almost always costs far more in labor and steel than the $1,000-$2,000 you would have spent just buying a High Cube container.

Do 20ft high cube containers exist?

Yes. While they are not as common in the global shipping fleet as 40ft HCs, they are readily available from container resellers. Many are “factory-made,” but a large number are professionally fabricated by cutting a 40ft HC in half and welding on a new steel end wall. This is a very common and reliable practice. Our plans that use 20ft containers specify High Cubes.

How much R-value can I fit in a high cube ceiling?

With a High Cube, you have ample room. You can easily create a ceiling assembly 5-8 inches deep. This allows for 4-6 inches of closed-cell spray foam, which can give you an R-value of R-28 to R-42, meeting the strict energy code requirements in even the coldest climates. We cover this in detail in our complete insulation guide.

Will my local building inspector really notice or care?

Yes, absolutely. Measuring for minimum ceiling height (IRC R305.1) is one of the fundamental checks they perform at a framing inspection. It’s a core life-safety and habitability standard, right alongside egress windows and stairway codes. They will have a tape measure, and they will use it. Trying to “get one past” the inspector is a recipe for a costly “Stop Work” order and a total loss of trust.

Do High Cube containers cost more to ship to my property?

No. The delivery cost (the “trucking”) from the container depot to your property is generally the same. It’s based on mileage, not the container’s height. The only consideration is ensuring the delivery route (and your property entrance) has a vertical clearance of at least 14 to 15 feet to be safe.

Start Your Build with Confidence.

Don’t risk your project on the wrong container. All our permit-ready plans are designed with High Cube containers to ensure you have a comfortable, spacious, and code-compliant home. Browse our collection and find the perfect design for your project.

Browse All PlansIf you love a design but need to move a window, we offer a plan modification service after purchase to help you customize it. Just contact us for a quote!

Important: Our plans are permit-ready but require review and stamping by a local licensed Professional Engineer (PE) in your jurisdiction. Final approval is subject to local building codes and regulations. We recommend consulting your local building department to verify all requirements.

Financial Disclaimer: Costs vary significantly by location, site conditions, and material choices. These are estimates for planning purposes only.

Refund Policy: Due to the digital nature of our plans, all sales are final. Please review our Refund Policy for details.